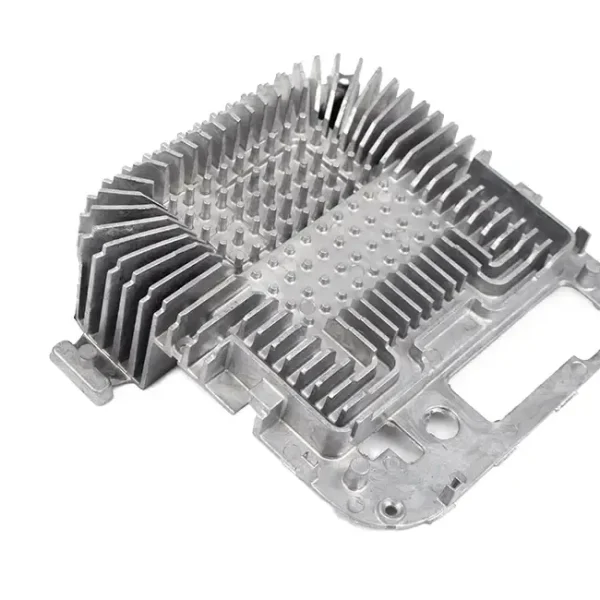

What is Injection Molding?

Injection molding is process tailored for producing large volumes of parts. Compared to other manufacturing technologies—like CNC machining and 3D printing—it requires an upfront, capital investment into tooling. But individual piece-part price will be substantially less when compared to other means of manufacturing plastic parts. This cost structure makes it an affordable solution for production runs.

It’s most often used for the manufacturing plastic parts at scale due to its low material waste and low cost per part. It’s an ideal manufacturing process for industries like medical devices, consumer products, and automotive to name a few.

Design Support

| Feature | Tip |

|---|---|

| Draft Angles | Apply 1–3° draft to improve part release and reduce tooling stress. |

| Wall Thickness | Keep walls uniform, 2–4 mm for most plastics, to avoid warping. |

| Radii & Corners | Add fillets (0.5–1 mm) to corners to improve strength and flow. |

| Ribs | Limit rib height to 3× wall thickness for stability and moldability. |

| Gate Placement | Position gates in thicker sections to ensure proper flow and reduce sink marks. |

Materials

Injection molding uses thermoplastics like Polypropylene (PP), Polyethylene (PE), ABS (Acrylonitrile Butadiene Styrene), Nylon (PA), and Polycarbonate (PC), chosen for properties like impact resistance, clarity, chemical resistance, and cost, to create diverse products from everyday items to medical devices, with materials heated, injected into molds, and cooled