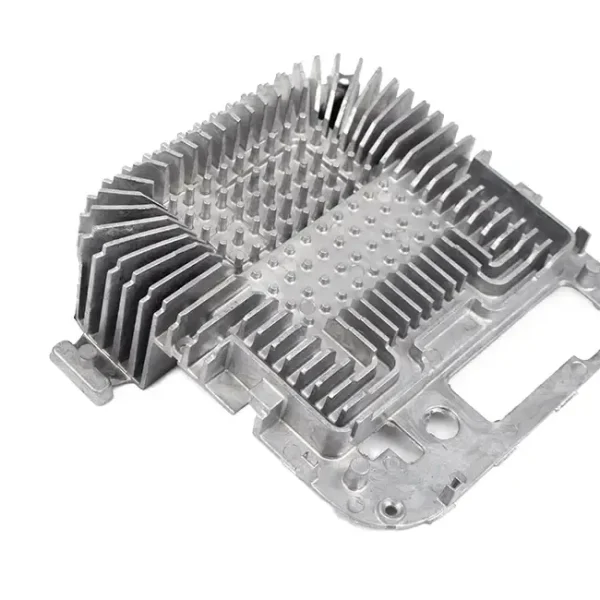

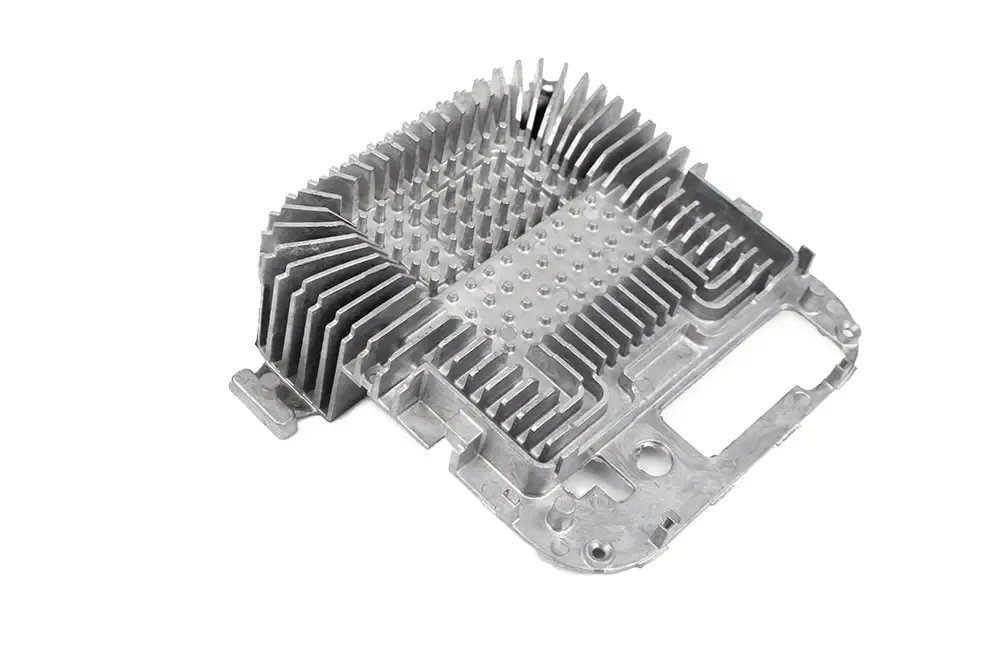

ALUMINUM DIE CASTING PARTS

Aluminum die casting is a metal-forming process that allows for the creation of complex aluminum parts. Ingots of aluminum alloy are heated to very high temperatures until they are entirely molten.

The liquid aluminum is injected under high pressure into the cavity of a steel die, also known as a mold — Generally, The die is made up of two halves, and after the molten aluminum has solidified, they are separated to reveal the cast aluminum part.

The resulting aluminum product is precisely formed with a smooth surface and often requires minimal or no machining processes. Given that steel dies are used, the process can be repeated many times using the same mold before it deteriorates, making aluminum die casting ideal for the high-volume production of aluminum parts.

MG-CNC Die Cast Advantages

With 11 years of manufacturing experience in China, MG-CNC Meta works with many world-class customers across North America, Europe and Asia. Ranging from industries such as automotive, powersports and more, we provide precision component manufacturing with some of the highest quality in the industry.

We are the first die casting part supplier that services well-known enterprises. Our quality, service and price are what set us apart. With our good reputation and quality service, we have won the praise of customers and the industry.

Die Cast Products

Ready To Start Your Next Project?